Why Your Boiler’s Water Quality Determines Its Fate

Boiler water treatment is the process of removing harmful impurities and adding protective chemicals to prevent scale formation, corrosion, and equipment failure in your heating system.

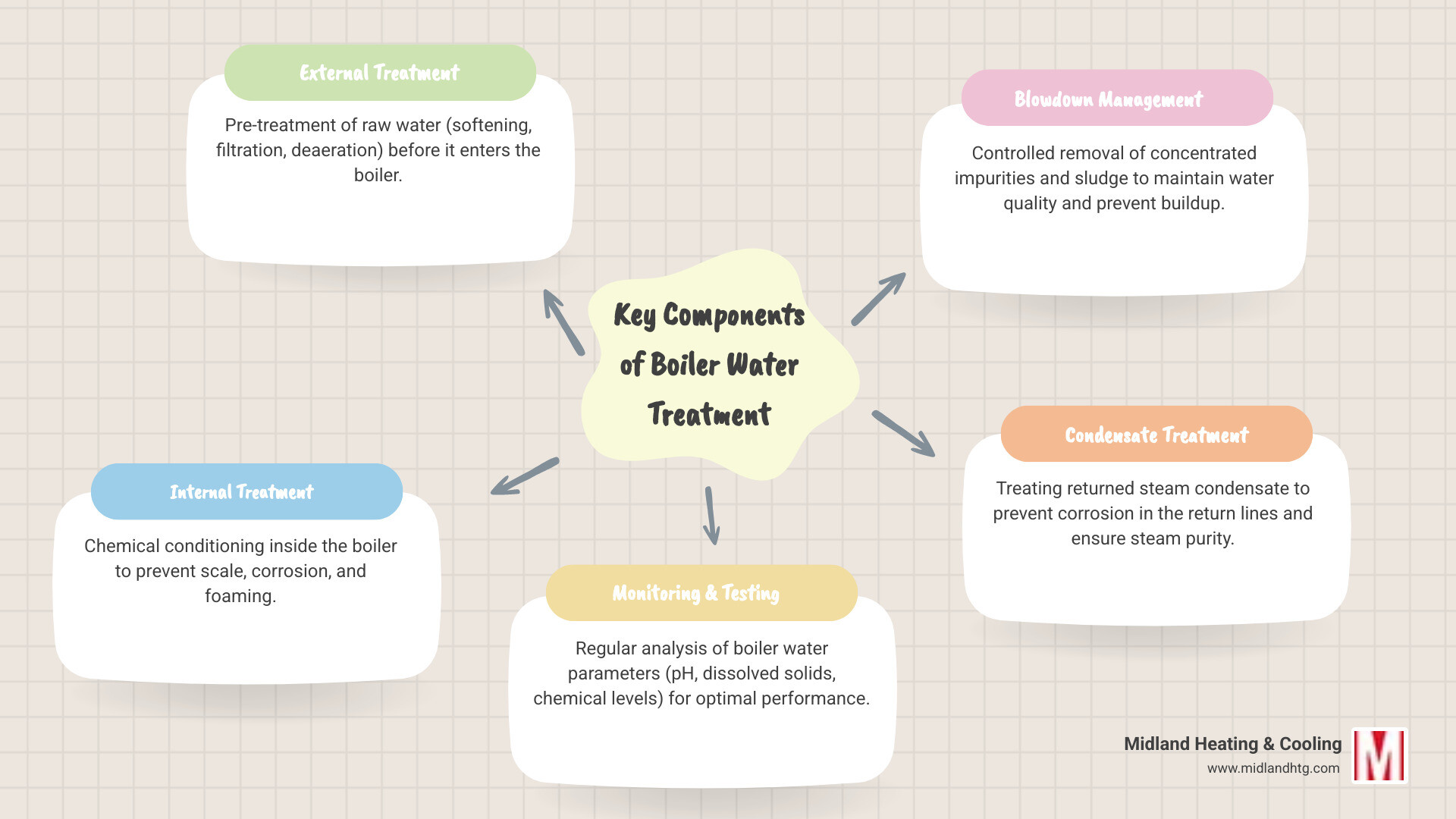

Key Components of Boiler Water Treatment:

- External Treatment – Water softening, filtration, and deaeration before water enters the boiler.

- Internal Treatment – Chemical conditioning inside the boiler to prevent scale and corrosion.

- Monitoring – Regular testing of pH, dissolved solids, and chemical levels.

- Blowdown – Controlled removal of concentrated impurities to maintain water quality.

Why It Matters:

- Prevents costly equipment failures and emergency repairs.

- Maintains heating efficiency and reduces fuel costs.

- Extends boiler lifespan from 15-20 years to potentially 30+ years.

- Ensures safe operation and high-quality steam production.

Your boiler is only as good as the water running through it. Scale and mineral buildup from hard water can hide in your pipes, only revealing themselves during a catastrophic emergency shutdown.

Without proper treatment, dissolved minerals like calcium and magnesium form rock-hard scale on heating surfaces. This scale acts like insulation, blocking heat transfer and forcing your system to work harder. Meanwhile, dissolved oxygen and acidic conditions eat away at metal components from the inside out.

A well-designed water treatment program can prevent these problems, keeping your Twin Cities home warm and your heating bills manageable.

The High Cost of Neglect: Why Untreated Water is a Boiler’s Worst Enemy

Skipping boiler water treatment is like slowly poisoning your heating system with contaminated water. Untreated water launches a full-scale attack on your boiler. Scale buildup acts like armor plating on boiler tubes, blocking heat transfer and forcing your system to burn more fuel. Corrosion eats away at metal components from the inside out, while sludge and foaming can damage equipment throughout your entire system.

The result is reduced efficiency, increased fuel costs, equipment failure, and serious safety hazards. Your boiler might start making strange noises, struggle to heat your home, or fail completely on the coldest day of winter.

If you’re noticing unusual sounds or climbing heating bills, it might be time to investigate. Check out these signs your boiler needs professional maintenance to see if your system is crying for help.

The Insulating Effect of Scale

Scale buildup on your boiler’s heating surfaces is like trying to cook while wearing thick winter gloves—frustrating and inefficient. Water hardness from dissolved calcium and magnesium is the main culprit. As water heats and turns to steam, these minerals form rock-hard deposits on your boiler tubes.

This unwanted insulation dramatically reduces heat transfer efficiency. Your boiler has to work much harder, leading to higher fuel consumption and energy bills. The trapped heat can also cause thermal fatigue in boiler tubes, potentially leading to cracks or complete failure.

A severely scaled boiler can fail within months instead of lasting decades, turning a minor water quality issue into a major replacement expense.

The Destructive Power of Corrosion

While scale blocks heat, corrosion is a more insidious threat, like rust happening inside your boiler where you can’t see it. Dissolved oxygen is a primary cause, with even tiny amounts leading to pitting corrosion that eats deep holes in boiler tubes. These pits can quickly become leaks, causing emergency shutdowns and expensive repairs.

Carbonic acid, formed when carbon dioxide dissolves in water, creates another problem. This acid attacks condensate return lines, causing a low pH environment that corrodes pipes and fittings, weakening components throughout your heating system.

Under-deposit corrosion is particularly sneaky, occurring beneath scale deposits where it goes undetected until serious damage is done. This type of corrosion often leads to the common boiler repair issues that catch homeowners off guard.

Sludge, Foaming, and Carryover

Untreated water also creates sludge, foaming, and carryover. Suspended solids and other impurities form sludge that settles in low-flow areas, causing restricted circulation and potentially dangerous overheating.

Foaming occurs when dissolved solids reduce water’s surface tension, creating a foam layer that interferes with steam production and leads to poor steam quality.

The worst-case scenario is priming, a violent ejection of boiler water into steam lines. This contaminated steam carries impurities throughout your system, damaging downstream equipment like heat exchangers and controls.

Fortunately, all these problems are preventable with proper boiler water treatment. A little prevention today saves thousands in repairs tomorrow.

A Comprehensive Guide to Boiler Water Treatment

Implementing a robust boiler water treatment program prevents equipment failures, improves performance, and controls costs. A well-controlled program reduces fuel costs, water usage, and environmental emissions by using chemistry, monitoring, and control solutions to mitigate corrosion and deposit formation. This proactive approach is a cornerstone of Why regular boiler service is important.

Step 1: External Treatment (Pre-Treatment)

Pre-treatment begins outside the boiler and is more reliable than internal treatment. It focuses on removing impurities from the makeup water before it enters the boiler, reducing the load on internal chemicals and extending system life. Hardness must be removed from the makeup water.

Common external treatment methods include:

- Water Softeners: Remove hardness-causing ions (calcium, magnesium) through ion exchange, preventing hard scale formation.

- Reverse Osmosis (RO): Uses a semi-permeable membrane to remove a high percentage of dissolved solids, which can significantly lower costs and extend equipment life.

- Ion Exchange (Demineralization): For high-purity needs, this removes virtually all dissolved mineral salts.

- Lime/Soda Softening: A traditional method using chemical precipitation to remove hardness and alkalinity.

- Deaeration: A crucial step to remove dissolved gases (oxygen, carbon dioxide) from feedwater, often by heating it.

These external treatments are vital for reducing the impurity load on the boiler. Many providers offer comprehensive Boiler water treatment equipment and services.

| Feature | External Treatment | Internal Treatment |

|---|---|---|

| Cost | Higher initial investment, lower ongoing chemical costs | Lower initial investment, higher ongoing chemical costs |

| Effectiveness | Highly effective at removing bulk impurities | Manages residual impurities and protects surfaces |

| Application | Pre-treatment of makeup water | Direct treatment within the boiler |

| Primary Goal | Reduce impurity load on boiler, protect equipment | Prevent scale/corrosion on boiler surfaces |

| Reliability | More reliable for preventing core issues | Supplements external treatment, crucial for fine-tuning |

Step 2: Internal Boiler Water Treatment

Even with external treatment, some impurities will enter the boiler, which is where internal boiler water treatment comes in. This involves adding specific chemicals directly to the boiler water to condition it and protect internal surfaces from scale, corrosion, and sludge.

Common internal treatment chemicals include:

- Oxygen Scavengers: Chemicals like sodium sulfite react with and remove residual dissolved oxygen in the feedwater.

- Scale Inhibitors / Dispersants: These prevent minerals from forming hard scale, instead creating a non-adherent sludge that is easily removed via blowdown. Phosphates are often used for this.

- Sludge Conditioners: Liquid conditioners that prevent the formation of solid, sticky deposits by keeping solids as small, non-agglomerated particles.

- pH Adjusters: Chemicals like caustic soda maintain the optimal pH range to prevent acidic corrosion and promote a protective magnetite layer on the boiler steel.

These treatments are part of a comprehensive program. For more details, consult resources on Boiler Water Treatment and Boiler Water Treatments and its purpose.

Step 3: Managing Condensate and Blowdown

The treatment cycle includes managing the steam that leaves and the water that remains.

-

Condensate Management: Steam condenses back into water after releasing its heat. This condensate is a valuable, pure resource. Recovering it is essential for energy and water conservation. However, condensate can become corrosive from carbonic acid, which forms when CO2 from makeup water dissolves in it.

- Neutralizing Amines: Added to boiler water, these volatilize with steam and dissolve in the condensate to raise its pH, neutralizing the acid.

- Filming Amines: These form a protective film on condensate return lines, acting as a physical barrier against corrosion.

Learn more about treating condensate and other AWT best practices for boiler systems.

-

Blowdown: As steam leaves, impurities concentrate in the boiler water. High concentrations can cause scaling, foaming, and carryover. Blowdown is the controlled removal of this concentrated water, which is replaced with fresh feedwater.

- Surface Blowdown: Removes water from near the surface to control dissolved solids.

- Bottom Blowdown: Removes accumulated sludge from the bottom of the boiler.

Proper, daily blowdown is crucial to manage high boiler solids and prevent issues. It’s a balance between removing impurities and not wasting excessive heat and chemicals.

Mastering Boiler Chemistry: Key Parameters to Monitor and Control

A successful boiler water treatment program isn’t a “set it and forget it” affair. It requires continuous vigilance and proactive management of water chemistry. Regular water testing and continuous monitoring of water chemistry are vital for improving boiler system reliability and ensuring safety. We take daily water samples to monitor chemical impurities in real-time. This active approach is one of the Essential tips for boiler maintenance.

The Importance of Proper Boiler Water Treatment Chemistry

Monitoring key parameters helps us understand the effectiveness of our treatment program and identify potential issues before they escalate.

- pH Levels: The pH factor is the most important factor influencing scale formation and the corrosive tendencies of boiler water. The pH should be maintained between a minimum of 10.5 and a maximum of 11.0 to prevent acidic corrosion of boiler tubes and plates, and to provide for the precipitation of scale forming salts before scale is deposited.

- Alkalinity: This refers to the water’s capacity to neutralize acids. The alkalinity of boiler water should be sufficiently high enough to protect shell and plates against acidic corrosion, but not high enough to produce carryover. A minimum value for alkalinity for adequate protection is 200 PPM. However, high boiler alkalinity, which is in excess of 700 PPM, should be avoided, as values higher than this can lead to embrittlement of the steel.

- Total Dissolved Solids (TDS): TDS represents the total concentration of all dissolved inorganic and organic substances in the water. High TDS levels can lead to foaming, priming, and carryover. TDS is best determined by a conductance test. We must control TDS through blowdown.

- Water Hardness: While external treatment aims to remove hardness, trace amounts can still enter the boiler. Total hardness should not exceed 50 PPM. In boilers, the hardness of the water can cause the formation of scale and sludge or mud.

- Dissolved Oxygen: As discussed, dissolved oxygen is a major cause of corrosion. The dissolved oxygen content should be maintained at a minimum, but at no time should it exceed 0.007 mg/l. The majority of corrosion problems are directly related to the quantity of dissolved oxygen in the boiler water.

Recommended Chemical Levels for Optimal Performance

Based on industry best practices and our experience, here are some recommended ranges for key boiler water treatment parameters:

- pH: Maintain between 10.5 and 11.0. This range prevents acidic corrosion and promotes the precipitation of scale-forming salts in a manageable form.

- Dissolved Oxygen: Keep below 0.007 mg/l. This is critical for preventing oxygen pitting corrosion.

- Sulfites (as SO3): Maintain a minimum of 20 PPM. Sulfites act as an oxygen scavenger, chemically removing residual dissolved oxygen.

- Alkalinity (as CaCO3): Aim for 200-700 PPM. This provides corrosion protection without contributing to excessive carryover. Values above 700 PPM should be avoided to prevent embrittlement.

- Total Hardness: Should not exceed 50 PPM in the boiler water. Ideally, it should be much lower in the feedwater after softening.

- Phosphates (as PO4): If using a phosphate treatment program, maintain a concentration between 30-50 PPM. This helps to precipitate remaining hardness as a non-adherent sludge.

These guidelines ensure that the boiler water environment is conducive to efficient heat transfer and long-term equipment integrity.

Understanding Different Types of Boilers and Their Needs

While the fundamental principles of boiler water treatment apply across the board, the specific needs can vary depending on the type and operating conditions of the boiler. For a deeper dive into boiler mechanics, check out our guide on Understanding different types of boilers.

- Shell Boilers (Fire-tube Boilers): These boilers typically operate at lower pressures and have a larger water volume in relation to their heating surface. They are generally more forgiving of higher levels of dissolved solids and can often be adequately treated with external softening and internal chemical conditioning.

- Water-tube Boilers: These boilers operate at higher pressures and have smaller water volumes with higher steam release rates. This makes them much less tolerant of impurities. Water-tube boilers are less tolerant of high TDS levels than shell boilers due to their limited water surface area, high steam release rates, and higher operating pressures.

- Superheaters: Many water-tube boilers incorporate superheaters, which heat the steam beyond its saturation point. Superheaters are particularly sensitive to carryover of contaminated water from the boiler, as impurities can deposit in the superheater tubes, leading to overheating and failure. Therefore, water-tube boilers often require more sophisticated external treatment (like RO or demineralization) to achieve very high purity feedwater.

The specific water treatment needs for different types of boilers necessitate a custom approach, considering factors like operating pressure, steam purity requirements, and the presence of superheaters.

The Payoff: Efficiency, Safety, and Longevity

Think of proper boiler water treatment as an investment that keeps paying dividends year after year. When you protect your boiler from scale, corrosion, and other water-related problems, you’re not just avoiding headaches – you’re open uping real benefits that show up in your energy bills, safety record, and equipment lifespan.

The math is simple: a well-maintained boiler runs more efficiently, lasts longer, and costs less to operate. It’s like the difference between driving a car with clean oil versus one that’s been neglected for years. This proactive approach is key to our Guide to extending boiler lifespan.

Maximizing Energy Efficiency and Reducing Costs

Here’s where boiler water treatment really shines – in your monthly energy savings. When your boiler is clean and properly treated, heat moves efficiently from the burner to your water or steam. No barriers, no waste, just smooth operation.

Improved heat transfer is the star of the show here. Scale buildup we talked about earlier? Even a thin layer acts like a winter coat on your boiler tubes, forcing your system to work harder and burn more fuel. Keep those surfaces clean, and heat flows freely where it needs to go.

This translates directly to lower fuel consumption. When your boiler doesn’t have to struggle against scale and deposits, it reaches target temperatures faster and maintains them with less effort. Many of our Twin Cities customers see noticeable drops in their heating bills after implementing a proper treatment program.

Reduced blowdown is another hidden benefit. With effective treatment keeping impurities under control, you don’t need to waste as much hot water through blowdown procedures. Every gallon you save is energy (and money) that stays in your system.

Don’t overlook condensate recovery either. That steam that condenses back into water? It’s essentially free distilled water that’s already hot. Maximizing your condensate return means less makeup water to heat and treat. For commercial applications, following ASHRAE standards for boiler efficiency ensures you’re getting the most from your investment.

Ensuring Safety and Steam Purity

Safety isn’t just a nice-to-have – it’s everything when it comes to boiler operation. Proper boiler water treatment prevents the kind of metal weakening that can lead to dangerous failures. Corrosion and scale don’t just hurt efficiency; they can create serious safety hazards.

Preventing boiler failure starts with understanding that water chemistry affects metal integrity. When pH levels drop too low or oxygen attacks metal surfaces, you’re looking at potential tube failures, leaks, or worse. A good treatment program keeps these threats in check before they become emergencies.

High-quality steam matters more than you might think. In industrial settings, contaminated steam can wreak havoc on downstream equipment. Turbines, heat exchangers, and process equipment all depend on clean steam to function properly. Carryover from poorly treated boiler water can cause expensive damage throughout your entire system.

Protecting downstream processes extends your investment protection beyond just the boiler itself. Whether you’re running a manufacturing process or need steam for sterilization applications, purity matters. Clean steam means reliable operations and fewer unexpected shutdowns.

Watch out for caustic embrittlement too. While alkalinity generally protects your boiler, too much of a good thing can cause a different kind of damage. When alkalinity exceeds 700 PPM, you risk a dangerous form of cracking in the boiler steel. Proper monitoring prevents this balance from tipping the wrong way.

Best Practices for Boiler Layup

Even boilers need their downtime. When your system goes offline for maintenance, seasonal shutdowns, or repairs, how you handle this “layup” period can make or break your equipment’s longevity. Think of it as putting your boiler to bed properly.

Wet layup works best for shorter breaks – maybe a month or less when you might need to fire up quickly. Fill the boiler completely with treated, deaerated water that’s loaded with oxygen scavengers and pH adjusters. This creates a protective environment that prevents corrosion while the system rests.

Dry layup is your go-to for longer shutdowns. Drain everything, clean thoroughly, and get those internal surfaces bone dry. Place moisture-absorbing chemicals like silica gel inside, along with vapor-phase corrosion inhibitors that create a protective atmosphere throughout the system.

Preventing off-season corrosion is crucial because oxygen loves to attack wet metal surfaces when there’s no circulation or heat. Use filming amines and other protective treatments to create barriers between metal and moisture. Done right, your boiler wakes up from its rest ready to perform like new.

The key is planning ahead. Don’t wait until the last minute to implement layup procedures. Proper preparation during shutdown prevents expensive surprises when you’re ready to start up again. For more guidance on keeping your system in top shape, check out our Top boiler maintenance tips.

Conclusion: Protect Your Investment with a Proactive Approach

Think of your boiler as the heart of your home’s heating system. Just like your heart needs clean blood to function properly, your boiler needs clean, properly treated water to keep your Twin Cities home warm and comfortable for decades to come.

Throughout this guide, we’ve seen how untreated water can transform from a helpful heating medium into your boiler’s worst enemy. Scale buildup acts like thick winter clothing on your boiler tubes, blocking heat transfer and forcing your system to work overtime. Meanwhile, corrosion silently eats away at metal components from the inside out, like rust attacking your car’s undercarriage during Minnesota’s harsh winters.

The problems we’ve explored – from the insulating effects of calcium and magnesium deposits to the destructive power of dissolved oxygen – aren’t just technical concerns. They translate directly into real-world headaches: skyrocketing fuel bills, unexpected breakdowns on the coldest days of the year, and potentially dangerous equipment failures.

But here’s the good news: boiler water treatment offers a clear path forward. A well-designed program that combines external pre-treatment, internal chemical conditioning, careful monitoring, and proper blowdown procedures can transform your boiler from a potential liability into a reliable, efficient heating partner.

The benefits speak for themselves. Proper treatment maximizes energy efficiency by ensuring optimal heat transfer, which means lower fuel consumption and reduced heating bills. It extends your equipment’s lifespan significantly – we’re talking about potentially doubling the useful life of your investment. Most importantly, it improves safety by preventing the weakening and failure of critical components.

The key is taking a proactive approach rather than waiting for problems to announce themselves. By the time you notice reduced performance or strange noises, damage may already be underway. Regular monitoring of pH levels, dissolved solids, and chemical concentrations helps catch issues before they become expensive repairs.

Every boiler system is unique, with different water quality challenges and operational demands. What works perfectly for a small residential shell boiler might be inadequate for a high-pressure water-tube system. That’s why partnering with experienced professionals who understand both the science of water chemistry and the practical realities of Twin Cities water conditions makes all the difference.

Since 1950, we at Midland Heating & Cooling have been helping Twin Cities families keep their homes warm and comfortable. Our certified technicians understand that proper boiler water treatment isn’t just about preventing problems – it’s about protecting your investment and ensuring reliable comfort for your family.

Don’t wait for warning signs to appear. A comprehensive water treatment program designed specifically for your system and local water conditions is one of the smartest investments you can make in your home’s heating infrastructure.

For expert evaluation and service on your boiler system in the Twin Cities, trust our certified technicians to ensure its safety and efficiency. Contact us for professional boiler repair and maintenance.