Why Your Furnace Heat Exchanger Matters More Than You Think

A furnace heat exchanger is the metal component inside your furnace that transfers heat from burning fuel to the air circulated throughout your home. It also keeps combustion gases separated from the air you breathe.

Quick Facts About Furnace Heat Exchangers:

- Primary Function: Separates dangerous combustion gases from breathable air while transferring heat

- Safety Role: Prevents carbon monoxide and other toxic gases from entering your home

- Lifespan: Typically lasts 10-20 years with proper maintenance

- Efficiency Impact: Secondary heat exchangers in high-efficiency furnaces boost performance to 90%+ AFUE

- Warning Signs: Strange smells, unusual noises, soot buildup, or irregular flame patterns

- Repair Reality: Cannot be repaired – replacement is the only safe option when cracked

When a heat exchanger fails, it is not just a comfort issue. A crack can allow carbon monoxide to leak into living spaces, creating a serious health hazard.

Knowing how this component works helps you spot issues early and choose repair vs. replacement wisely. In Minnesota’s harsh winters, your family’s safety and warmth depend on a properly functioning heat exchanger.

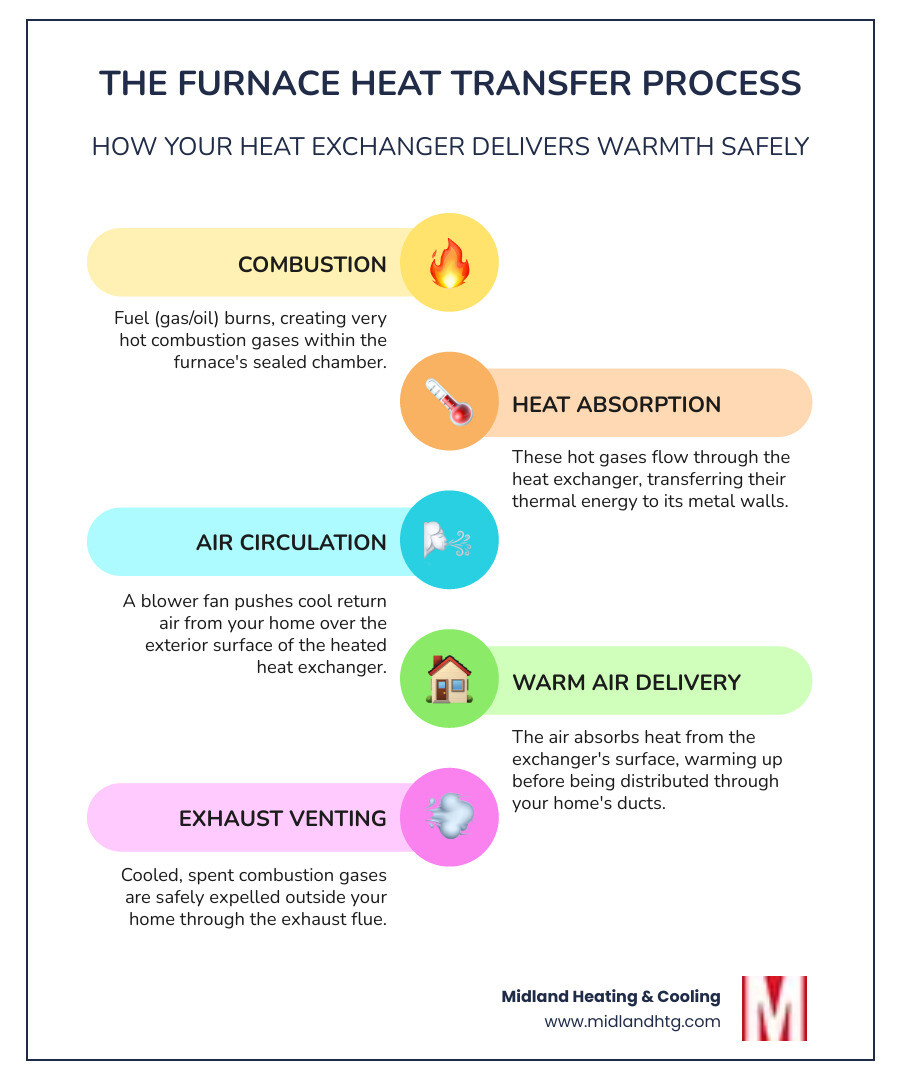

What Is a Furnace Heat Exchanger and How Does It Work?

Your furnace heat exchanger is the heart of your heating system. It safely warms the air flowing through your home while keeping dangerous combustion gases completely separate from the air you breathe.

When fuel ignites in the combustion chamber, it creates hot flue gases containing carbon monoxide. The heat exchanger acts as a protective barrier, preventing these harmful byproducts from circulating in your home. Hot combustion gases flow through the heat exchanger’s sealed chambers or tubes. Simultaneously, your furnace blower pushes cool air from your home over the outside of these hot metal surfaces. The air absorbs the thermal energy, gets warmed up, and then travels through your ductwork to warm your house.

Meanwhile, the cooled combustion gases are safely vented outside through your flue pipe. This sealed design is critical for safety, which is why any crack or damage is a serious concern. You can learn more about what HVAC heat exchangers are and their role in your system.

The Primary Function of a Furnace Heat Exchanger

Your furnace heat exchanger has three essential jobs that it performs flawlessly when everything’s working properly. First, it separates breathable air from dangerous combustion gases – this is literally a matter of life and death. Second, it contains those combustion gases in a sealed pathway so they can’t leak into your home. Third, it transfers thermal energy from the hot gases to the air circulating through your house.

The metal construction is specifically designed for this demanding job. You’ll typically find heat exchangers built in either a clamshell design (which looks like two metal shells joined together) or a tubular design (featuring multiple tubes that the gases flow through). Both designs maximize the surface area where heat transfer happens while maintaining that crucial separation between combustion gases and your indoor air.

Primary vs. Secondary Heat Exchangers

Here’s where things get interesting – not all furnaces use the same heat exchanger setup, and it makes a big difference in efficiency and performance.

Standard efficiency furnaces (those with 70-80% AFUE ratings) use just one primary heat exchanger. This single unit captures a good amount of heat from the combustion process, but some heat still escapes up the chimney with the exhaust gases. These furnaces have been reliable workhorses for decades, and many Minnesota homes still depend on them.

High-efficiency furnaces take things to the next level with both primary and secondary heat exchangers. After the hot gases pass through the primary heat exchanger, they’re not done yet. They move into a secondary heat exchanger that squeezes out even more heat – so much that water vapor in the exhaust actually condenses into liquid. This process captures what’s called latent heat and is why these units are called condensing furnaces.

The secondary heat exchanger faces a unique challenge because that condensation is acidic and corrosive. That’s why manufacturers build them from stainless steel or specially coated materials that can handle the harsh conditions. This extra heat recovery is what pushes these furnaces to increased AFUE ratings of 90% or higher, making them incredibly efficient at capturing heat that would otherwise be wasted.

For Minnesota homeowners dealing with long, cold winters, that extra efficiency can mean significant savings on heating bills while keeping your home consistently comfortable.

Signs of a Damaged Heat Exchanger: A Homeowner’s Guide

A furnace heat exchanger rarely fails overnight; it usually gives warnings. If you notice any of the red flags below, call us right away. For a broader look at furnace problems, check out our guide on signs you need furnace repair.

Unusual Noises and Smells

Listen for rattling or popping during startup. Cracked metal expands and contracts unevenly, causing noises. Banging on startup can also point to internal issues.

Smells matter too. A metallic or burning plastic odor can indicate overheating or escaping combustion gases. A strong formaldehyde-like or sour smell (often described as sour pickles or mothballs) is a serious warning that combustion gases may be leaking into your home’s air. That is different from the mild burning-dust smell at first startup each season.

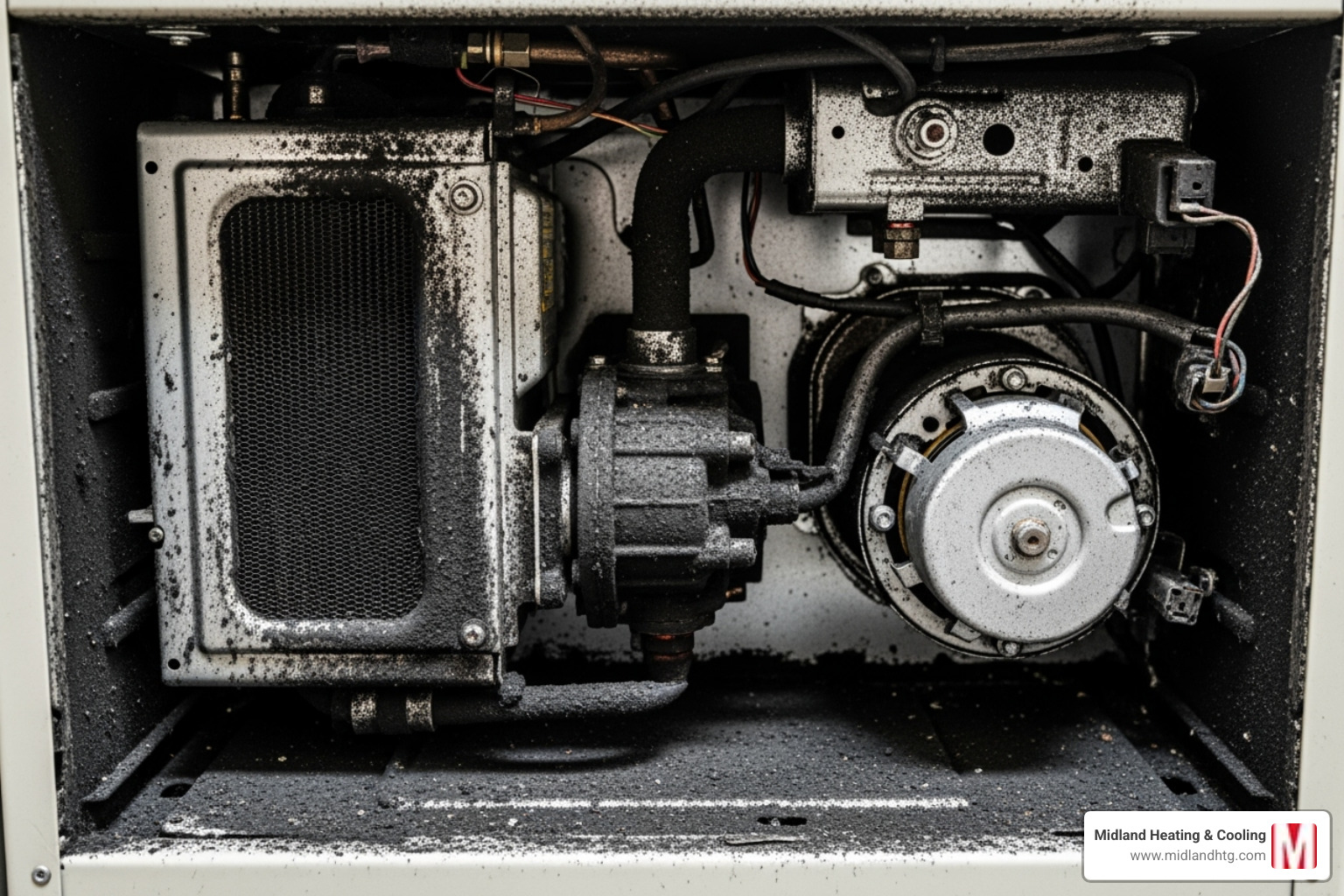

Visual Cues and Performance Issues

Look for soot or black residue in the furnace cabinet, especially around burners or the heat exchanger. It suggests incomplete combustion. Excessive corrosion or rust flakes can signal material breakdown. Water pooling near the base can indicate condensation problems in high-efficiency units.

Check the burner flame pattern. Flames should be steady and blue. Yellow or flickering flames, especially when the blower starts, can indicate a crack affecting airflow.

Finally, watch for declining performance: longer run times, rooms that do not warm up, or sudden energy bill spikes. A compromised furnace heat exchanger often reduces heat transfer efficiency and forces the system to work harder.

The Critical Dangers of a Cracked Heat Exchanger

When a furnace heat exchanger develops even a small crack, it becomes an immediate safety hazard. The sealed barrier that keeps combustion gases out of your breathable air is compromised, often leading to incomplete combustion and other dangerous conditions.

A serious risk is flame rollback, where flames move backward toward the gas supply instead of staying in the combustion chamber. This creates a fire hazard and requires prompt professional attention.

The Silent Threat of Carbon Monoxide (CO)

Carbon monoxide is colorless and odorless. A cracked heat exchanger can let CO mix with the air circulating through your home. CO poisoning symptoms often resemble flu-like illness: headaches, dizziness, nausea, fatigue, confusion, or shortness of breath. Prolonged exposure can be life-threatening.

This is why CO detectors are essential in any home with fuel-burning appliances. The EPA provides excellent guidance on choosing and maintaining carbon monoxide detectors.

If a CO alarm sounds, evacuate immediately, call 911, and do not re-enter until first responders give the all-clear. We have served Minnesota families since 1950 and know that with heat exchanger safety, caution is always the right choice.

Repair or Replace? Making the Right Decision

When your furnace heat exchanger is damaged, you have two options: replace the exchanger or install a new furnace. The right choice depends on age, warranty, efficiency, and overall system condition. For guidance on when full replacement makes sense, see when to opt for furnace replacement.

Cost Factors for Replacing a Furnace Heat Exchanger

Costs vary by brand, model, and efficiency level. The part itself can be expensive, especially in high-efficiency furnaces with secondary exchangers. Labor is significant because the job typically takes 6 to 8 hours and requires extensive disassembly and reassembly by certified technicians.

Location and accessibility matter; cramped spaces increase labor time. Proprietary designs can be harder to source and may extend timelines. High-efficiency, condensing systems also need careful handling due to corrosive condensate and additional components.

Comparing Heat Exchanger Replacement vs. Full Furnace Replacement

| Factor | Replacing Heat Exchanger | Replacing Entire Furnace |

|---|---|---|

| Initial Cost | Lower upfront investment | Higher upfront investment |

| Lifespan | Extends current furnace life by a few years | Provides a brand-new system with full expected lifespan |

| Warranty | New part warranty; existing furnace warranty may be voided | Full new furnace warranty (parts and labor) |

| Efficiency | Maintains current furnace efficiency | Significant efficiency gains with modern technology |

| Reliability | Other aging components may still fail soon | Complete system reliability with fewer unexpected issues |

| Peace of Mind | Temporary solution if other parts are showing wear | Long-term confidence in your heating system |

If your furnace is under about 10 years old, still under warranty, and the furnace heat exchanger is the only major issue, replacing the exchanger can make sense. For systems 10-15+ years old, a full replacement often delivers better long-term value, higher efficiency, and fewer surprise repairs.

Maintenance and Longevity: Protecting Your Investment

Think of your furnace heat exchanger like an engine: consistent care keeps it safe and efficient. After decades serving the Twin Cities, we know proper maintenance can extend exchanger life to 20+ years while protecting your family through long Minnesota winters.

The good news: it is mostly about consistency and catching small issues early.

Recommended Maintenance Practices

- Annual professional inspections: Our technicians use cameras to check for hairline cracks and verify clean combustion and proper venting.

- Regular filter changes: A clogged filter overheats the heat exchanger. Replace every 1-3 months (more often with pets) to protect equipment and enjoy cleaner indoor air.

- Keep vents clear: Do not block supply or return vents; balanced airflow reduces stress on the exchanger.

- Maintain clearance around the furnace: The unit needs open space for airflow and safe operation.

Follow these simple steps and schedule your annual inspection with our team for safety, efficiency, and fewer breakdowns. For a complete checklist, see our effective furnace maintenance tips.

Frequently Asked Questions about Furnace Heat Exchangers

Over our decades serving the Twin Cities, we hear these questions most often about furnace heat exchangers.

What is the typical lifespan of a furnace heat exchanger?

Most furnace heat exchangers last 15 to 20 years. Lifespan depends on maintenance, material quality, and operating conditions. Annual tune-ups and good airflow (clean filters, open vents) reduce thermal stress and extend life.

Can a cracked heat exchanger be repaired?

No. A cracked furnace heat exchanger cannot be safely repaired. Welding or brazing is ineffective and often prohibited. Replacement is the only safe option. We will review whether replacing the exchanger or upgrading the furnace is the better investment for your home.

How do technicians confirm a heat exchanger is cracked?

We combine methods for accuracy: visual inspection, camera scope inspection (borescope), combustion analysis, pressure testing, and flame pattern observation. When we confirm a crack, we show you the evidence and explain next steps clearly.

Your Family’s Safety is Our Priority

Your furnace heat exchanger quietly protects your home by separating combustion gases from the air you breathe. If it is damaged, safety comes first.

Since 1950, Midland Heating & Cooling has helped Twin Cities families with honest assessments, certified technicians, and maintenance that prevents problems before they start. Regular service is about more than avoiding breakdowns; it is about peace of mind.

If it has been over a year since your last inspection, or you have noticed warning signs, we are ready to help. Schedule your HVAC service in Minneapolis, MN and let our team ensure your system is safe and reliable.